The effort to improve quality in manufacturing has transformed from its original emphasis on quality through inspection to today's focus on quality through the development of standardized processes capable of consistently delivering value to the customer.

Quality improvement is achieved by focusing on customer value, keeping employees actively engaged, and continually experimenting with adjustments to processes related to production, procurement, facilities, and more. Successful manufacturers prioritize effective problem-solving, team collaboration, and strong leadership.

While the concept of continuous improvement is not new to manufacturing, the modern approach to improvement involves deploying software to support the effort to eliminate the cost of poor quality. KaiNexus is proud to empower our manufacturing clients to reach their goals with a platform that serves as a repository of knowledge for executives and frontline workers alike. Our customers have access to real-time data to increase efficiency, lower cost, and improve quality at every stage of production.

The bedrock principle of quality improvement in manufacturing is that everyone in the organization is responsible for identifying opportunities for improvement. Sometimes, ideas for innovation come from the executive team, but more often, they are submitted by frontline assembly workers, floor managers, supply chain supervisors, facility managers, operations supervisors, and others. Inviting input from floor workers allows manufacturing organizations to implement quality control at the earliest stages of production. The challenge is getting everyone on the same page in a large, diverse organization. KaiNexus provides the accessibility, custom configuration, and simplicity that large scale manufacturers need to standardize improvement efforts from the frontlines to the board room.

Capture incremental improvements and large events in a single online platform. Align all improvements up to your strategic goals. One method, endless applications.

Empower every worker to submit ideas for positive change whenever the inspiration strikes. Engage anywhere, from any device. Check out KaiNexus Mobile to learn more.

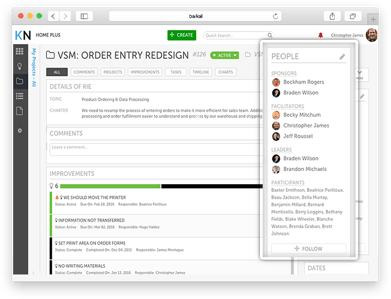

Configure template and board displays to fit your specific needs for every type of improvement and project. If you have a layout that works, you can use it in KaiNexus.

KaiNexus is so intuitive that even the least tech-savvy employees can use it with little to no training. You can concentrate on improvement, not technology.

Manufacturing organizations discover that waste occurs during the transition from one team or functional area to another. Therefore, the improvement ideas that will significantly impact cost and quality require cross-functional collaboration. KaiNexus brings together the organization by giving every department one place to go for improvement work.

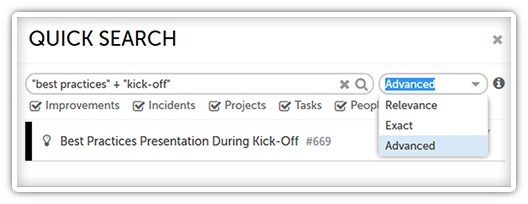

KaiNexus becomes your organization's repository of tribal knowledge. It's easy to find past improvements, A3s, PDSAs, and value stream maps based on keywords or project category. You are in the position to build on past successes and learn from ideas that didn't work.

When a process improvement is successful, it is the best practice to recognize and acknowledge the team members who made it possible. Sharing results and celebrating success is how leaders cultivate a culture that prioritizes improvement and shares lessons learned. KaiNexus makes this a built-in part of the process with our improvement broadcasting features.

If your manufacturing organization has facilities worldwide, your quality improvement software must support multiple languages, time zones, and currencies. The KaiNexus platform makes international collaboration possible regardless of location or language.

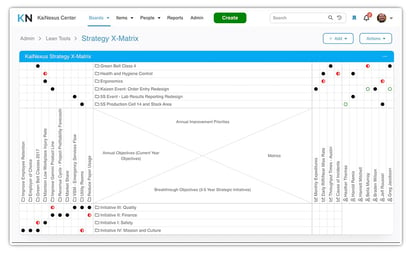

Continuous improvement is only possible when everyone is working toward the same objectives. In the best case, all improvement projects are linked to the most critical strategic goals of the organization. KaiNexus helps leaders in strategy deployment as they cascade goals down from the company level to each individual worker. Our goal-setting features let everyone understand their role in achieving the objectives necessary to succeed in the marketplace.

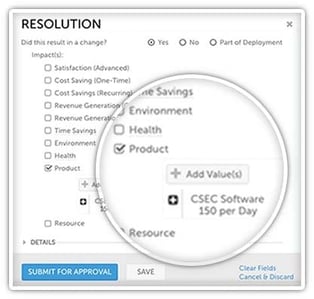

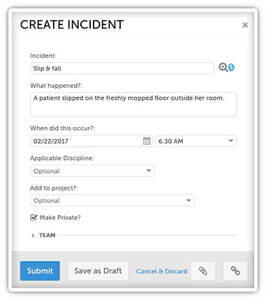

Unexpected incidents happen, but they should only occur one time. With KaiNexus, workers can report any kind of incident from accidents to equipment malfunctions, so every incident leads to improvement. With KaiNexus, you can ensure that everyone knows the root cause of the incident and the corrective action to prevent a recurrence.

People understand images much more quickly and intuitively than text. That's why the KaiNexus solution for manufacturing includes charts, graphs, and dashboards that make it easy to comprehend the progress of projects and the organization's improvement culture's overall health.

People are reluctant to use any software tool that doesn't help them do better work. That's why KaiNexus is configurable so that each team member gets the information they need for their role and responsibilities. This capability especially important in manufacturing because there are many widely varied roles.

Manufacturing leaders have the task of creating a culture that supports the continuous pursuit of improvement. Getting there requires information about the people, teams, and departments that are actively engaged in improvement work. KaiNexus delivers that knowledge with real-time reports that show the number of improvement projects in progress, who's involved, and how each improvement impacts important measurements like cost and productivity.

KaiNexus includes email notifications and alerts to keep everyone up to speed on each improvement project's progress and speed the pace of change. Notifications let managers know when a new opportunity for improvement has been proposed and requires review. Email alerts make it clear when action is required so that supervisors can ensure that no project falls through the cracks.

When you join the KaiNexus community, you get a dedicated account team that partners with you to build your improvement culture. We document how you currently do things, understand what you'd like to improve, and identify your goals. Then we work together to configure KaiNexus to fit your precise needs.

Technology should never stand between your people and improvement. That's why we customize a training plan specific to your manufacturing organization. You'll have access to a combination of live and recorded custom training sessions that address your specific priorities, use-cases, and team composition.

Data security must always be a top concern for manufacturing organizations implementing any kind of software. It is vital when the solution stores information such as improvement data, which is highly confidential. With KaiNexus's built-in security features, there's no need to worry about unauthorized access.

Copyright © 2026

Privacy Policy