Operational excellence is a strategic approach to achieving superior organizational performance by focusing on continuous improvement and optimizing workflows. It involves a combination of leadership, team alignment, and a culture of continuous learning to ensure every aspect of the business is operating at its highest potential. This concept transcends traditional management practices by emphasizing the importance of value creation for customers, minimizing waste, and enhancing overall efficiency. In today's highly competitive and fast-paced business environments, the ability to define operational excellence in business has become a critical differentiator that enables companies to stay ahead by consistently delivering high-quality products and services.

What is the role of operational excellence?

The significance of achieving operational excellence lies in its holistic approach to managing workflows and improving efficiency across all levels of an organization. It requires a deep understanding of the entire value chain and its interdependencies. This comprehensive approach ensures that operational improvements are sustainable and scalable, leading to long-term success and resilience in an ever-changing market landscape. Through operational excellence, companies enhance their current performance and build a strong foundation for future growth and innovation.

By integrating the principles of operational excellence such as Lean, Six Sigma, and Total Quality Management, businesses can systematically identify and eliminate inefficiencies, reduce costs, and improve customer satisfaction.

Lean management is a systematic approach to running an organization that supports the concept of continuous improvement, a long-term strategy aimed at optimizing efficiency and quality while minimizing waste. Originating from the Toyota Production System, Lean practices deliver maximum value to the customer by eliminating non-value-added activities, or "waste," from processes. This is achieved through principles such as value stream mapping, just-in-time production, and the implementation of a pull system to ensure that resources are only used when needed. Lean management fosters a culture of empowerment among employees, encouraging them to identify inefficiencies and contribute to the continuous improvement process.

The role of Lean thinking in achieving operational excellence is pivotal, as it provides the tools and methodologies to streamline processes, enhance productivity, and improve quality. By adopting Lean core principles, organizations can create more value with fewer resources, which leads to higher customer satisfaction and competitive advantage. Lean management emphasizes the importance of a holistic workflow view, ensuring that every step in the process adds value and is as efficient as possible. This alignment of resources and processes with customer needs ensures that the organization can respond swiftly to changes in customer demand and maintain high levels of performance and innovation. Consequently, Lean management is an essential component of operational excellence, driving sustainable improvements and fostering a culture of continuous development.

Six Sigma is a data-driven methodology focused on minimizing defects and optimizing processes by improving quality and efficiency. Rooted in statistical analysis, Six Sigma aims to reduce process variation and eliminate errors to achieve near-perfect outcomes. The primary goal of Six Sigma is to reach a defect rate of no more than 3.4 defects per million opportunities, a standard that ensures exceptionally high quality. The methodology follows a structured framework known as DMAIC, which stands for Define, Measure, Analyze, Improve, and Control. Each phase of DMAIC provides a systematic approach to problem-solving and process improvement, ensuring that every aspect of a process is scrutinized and optimized.

By systematically applying these phases, Six Sigma helps the entire organization achieve operational excellence through significantly improved quality, efficiency, and customer satisfaction. The rigorous focus on data and process standardization leads to consistent, reliable outcomes, thereby supporting the broader goal of operational excellence.

Fostering a culture that embraces constant improvement is crucial for organizations aiming to achieve long-term success and adaptability in a rapidly changing business environment. A culture of continuous improvement encourages every member of the organization, from executives to frontline employees, to constantly seek ways to enhance processes, products, and services. This mindset promotes innovation, agility, and resilience, enabling companies to respond proactively to market changes, technological advancements, and evolving customer needs. By prioritizing improvement at all levels, organizations can maintain a competitive edge, drive higher efficiency, and deliver exceptional customer value.

When employees are encouraged to identify and solve problems, they become more invested in their roles and the organization's success. This sense of ownership and accountability fosters a positive work environment where creativity and collaboration thrive. A continuous improvement culture supports the systematic application of Lean and Six Sigma methodologies, ensuring that improvements are data-driven, sustainable, and aligned with strategic goals. Ultimately, embracing constant improvement enhances operational performance and cultivates a dynamic, forward-thinking organization capable of navigating the complexities of today's business world.

Building operational excellence into strategic business planning ensures efficient, effective, and sustainable operations support an organization's long-term goals. Operational excellence methodologies align day-to-day activities with the business strategy, enabling businesses to deliver consistent quality, reduce costs, and enhance customer satisfaction. By integrating operational excellence into strategic planning, organizations can proactively identify and address inefficiencies, drive continuous improvement, and foster innovation, all of which are critical for maintaining competitiveness in a dynamic market environment.

Here are the steps for integrating operational excellence strategies into business planning:

Define Strategic Objectives: Begin by clearly articulating the organization's strategic goals. These should include a long-term vision, mission, and specific, measurable objectives the business aims to achieve. Understanding these goals is essential for aligning operational excellence initiatives with the overall strategy.

Assess Current State: Conduct a thorough analysis of the current business and operational processes, including strengths, weaknesses, opportunities, and threats (SWOT analysis). This assessment should collect data on key performance indicators (KPIs), process efficiencies, and customer feedback.

Identify Key Processes: Determine the critical processes directly impacting the strategic objectives. These processes are the primary focus areas for operational excellence initiatives. Mapping the value stream for these processes helps identify waste and areas for improvement.

Set Improvement Targets: Establish specific, achievable targets to improve business processes that align with strategic goals. These targets should be based on the analysis of the current state and should address fundamental inefficiencies, quality issues, and cost drivers.

Develop a Roadmap: Create a detailed plan outlining the steps, timelines, and resources required to achieve the improvement targets. This roadmap should include milestones, roles and responsibilities, and a clear timeline for implementing operational excellence initiatives.

Implement Improvement Initiatives: Execute the improvement initiatives using Lean, Six Sigma, or Total Quality Management (TQM) methodologies. Ensure that all levels of the organization are engaged and that continuous learning and adaptation are emphasized.

Monitor and Measure Progress: Continuously use KPIs and other metrics to track progress against the set targets. Regular monitoring helps identify deviations from the plan and make necessary adjustments. This step ensures that improvements are sustained and aligned with strategic objectives.

Foster a Continuous Improvement Culture: Encourage a culture of continuous improvement by recognizing and rewarding efforts, promoting employee engagement, and providing training and development opportunities. A culture that embraces constant improvement supports the ongoing success of operational excellence initiatives.

Review and Adjust: Periodically review the outcomes of the operational excellence initiatives and their impact on strategic goals. Use this review to refine strategies, update the roadmap, and set new improvement targets. This iterative process ensures that operational excellence remains a core component of strategic business planning.

By following these steps, organizations can effectively integrate operational excellence into their strategic business planning, leading to enhanced performance, sustainable growth, and a solid competitive position in the market.

Technology facilitates operational excellence by providing tools and systems that streamline processes, enhance efficiency, and enable data-driven decision-making. By integrating advanced technologies, organizations can automate repetitive tasks, monitor performance in real-time, and foster a culture of continuous improvement. By leveraging technology, businesses can optimize their operations, reduce errors, and respond swiftly to changing market demands, achieving superior performance and maintaining a competitive edge.

Here are examples of operational excellence in the IT industry:

Enterprise Resource Planning (ERP) Systems: ERP systems integrate various business processes, such as finance, supply chain, manufacturing, and human resources, into a single unified system. This integration enhances data visibility, facilitates seamless information flow, and improves department coordination. Examples include SAP, Oracle ERP, and Microsoft Dynamics 365.

Customer Relationship Management (CRM) Systems: CRM tools help organizations manage interactions with current and potential customers by centralizing customer data, automating sales processes, and providing insights into customer behavior. This improves the customer experience, boosts sales efficiency, and enhances customer satisfaction. Examples include Salesforce, HubSpot, and Zoho CRM.

Business Intelligence (BI) and Analytics Tools: BI and analytics platforms enable organizations to collect, analyze, and visualize data to make informed decisions. These tools help identify trends, monitor key performance indicators (KPIs), and uncover insights that drive process improvements. Examples include Tableau, Power BI, and Qlik.

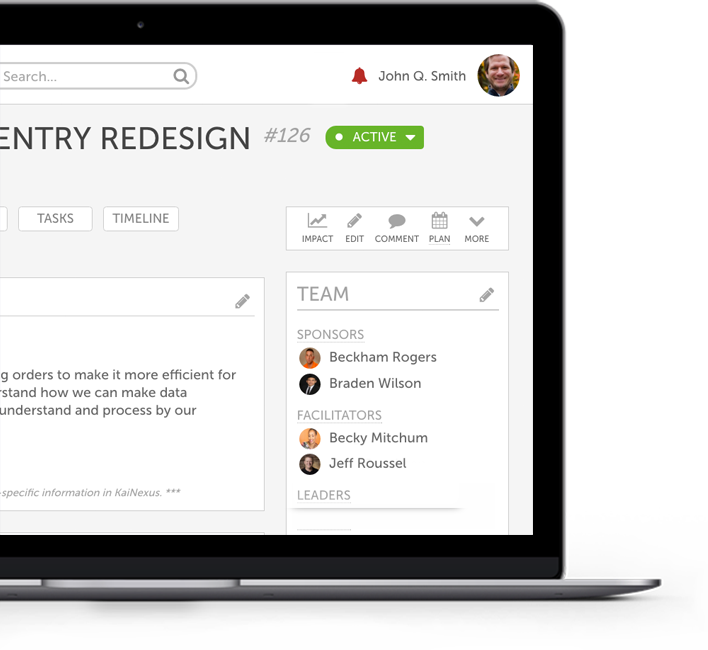

Lean and Six Sigma Software: These tools support process improvement methodologies by providing data collection, analysis, and project management features. They help streamline processes, reduce waste, and enhance quality. Examples include KaiNexus, Minitab, JMP, and SigmaXL.

Robotic Process Automation (RPA): RPA tools automate repetitive, rule-based tasks across various business functions. By using software robots to handle mundane activities, organizations can reduce errors, lower operational costs, and free up employees for more strategic tasks. Examples include UiPath, Blue Prism, and Automation Anywhere.

Internet of Things (IoT) Platforms: IoT devices and platforms enable real-time monitoring and management of physical assets and processes. In manufacturing, IoT sensors can track equipment performance, predict maintenance needs, and optimize production lines. Examples include PTC ThingWorx, Siemens MindSphere, and GE Predix.

Workflow Automation Tools: These tools streamline business processes by automating routine workflows, approvals, and communications. They improve efficiency, reduce bottlenecks, and ensure consistent execution of tasks. Examples include Zapier, Nintex, and IBM Business Automation Workflow.

By incorporating these and other technological tools, organizations can drive operational excellence, ensuring that processes are optimized, resources are utilized efficiently, and continuous improvement is embedded in the company culture. This technological integration enhances current performance and positions businesses for future growth and innovation.

Measuring the effectiveness of operational practices is crucial for ensuring continuous improvement and aligning operations with strategic goals. Metrics and analytics provide the data to evaluate performance, identify inefficiencies, and drive decision-making. Here are key metrics and analytics used to measure the effectiveness of operational practices:

Key Performance Indicators (KPIs): KPIs are specific, quantifiable measures that reflect critical business success factors of an organization. Common operational KPIs include:

Cycle Time: The total time required to complete a process from start to finish. Shorter cycle times indicate higher efficiency.

Throughput: The rate at which products or services are produced and delivered. Higher throughput reflects improved productivity.

First Pass Yield (FPY): The percentage of products or services that meet quality standards without rework. Higher FPY indicates better quality control.

Overall Equipment Effectiveness (OEE): A comprehensive metric that evaluates the efficiency of manufacturing equipment by considering availability, performance, and quality.

Cost Per Unit: The total cost associated with producing a single unit of product or service. Lower costs per unit suggest more efficient operations.

Operational Efficiency Metrics:

Resource Utilization: Measures how effectively an organization uses its resources, such as labor, machinery, and materials. High utilization rates indicate optimal use of resources.

Inventory Turnover: The number of times inventory is sold and replaced over a specific period. Higher turnover rates signify efficient inventory management.

Order Fulfillment Time: The time taken from receiving an order to delivering it to the customer. Shorter fulfillment times improve customer satisfaction and operational efficiency.

Quality Metrics:

Defect Rate: The number of defects per unit produced. A lower defect rate indicates higher product quality and process effectiveness.

Customer Complaints: The number of complaints received from customers. Fewer complaints reflect better service and product quality.

Return Rates: The percentage of products returned by customers. Lower return rates suggest better quality control and customer satisfaction.

Financial Metrics:

Operating Margin: The percentage of revenue remaining after deducting operating expenses. Higher operating margins indicate better cost management and profitability.

Return on Assets (ROA): A measure of how efficiently an organization uses its assets to generate profit. Higher ROA reflects effective asset utilization.

Employee Performance Metrics:

Employee Productivity: The output produced by employees in a given period. Higher productivity rates indicate efficient labor management.

Employee Turnover Rate: The percentage of employees who leave the organization within a specific period. Lower turnover rates suggest a stable and satisfied workforce.

Operational excellence offers many advantages that drive an organization towards sustained success and competitive advantage. Businesses can enhance quality, reduce costs, and significantly improve customer satisfaction by focusing on continuous improvement and efficiency.

What does operational excellence do?

Reduced costs are a direct outcome of streamlined operations under operational excellence. Businesses can significantly reduce unnecessary expenses by minimizing waste, lowering defect rates, and improving productivity. Efficient resource use, enhanced quality control, and faster cycle times contribute to lower operational costs, allowing organizations to allocate savings to strategic initiatives and innovation. This cost reduction boosts profitability and provides a competitive edge in the market.

Enhanced customer service is a natural outcome of these operational improvements. Efficient operations allow employees to focus more on customer needs, respond quickly to inquiries, and provide accurate information. Higher product quality and timely delivery build customer trust and loyalty. As customer satisfaction grows, it drives repeat business and positive word-of-mouth. It creates a virtuous cycle where operational excellence continually fuels superior customer service, leading to sustained business growth and success.

Operational excellence provides businesses with a significant edge by enabling them to consistently deliver high-quality products and services while maintaining efficiency and cost-effectiveness. In today's fast-paced and dynamic market environment, customers expect quick responses, reliable products, and exceptional service. Organizations that excel in operational efficiency can more effectively meet these expectations, gaining a competitive advantage over their counterparts.

Operational excellence supports innovation and growth by freeing up resources and fostering a culture of creativity and experimentation. Businesses can redirect time, money, and talent towards research, development, and strategic initiatives by optimizing operations. This allows them to innovate more effectively, introduce new products and services, and expand into new markets, further solidifying their competitive position.

Toyota Motor Corporation: Toyota is renowned for its commitment to operational excellence, epitomized by the Toyota Production System (TPS). One notable achievement resulting from Toyota's operational excellence is its industry-leading efficiency in manufacturing. Through principles such as Just-In-Time production and continuous improvement (Kaizen), Toyota has achieved remarkable reductions in production lead times, inventory levels, and manufacturing defects. This has enabled Toyota to consistently deliver high-quality vehicles to customers while maintaining cost-effectiveness and competitiveness in the global automotive market.

Amazon.com, Inc.: Amazon is celebrated for its relentless focus on operational excellence across its vast e-commerce and logistics operations. A key achievement stemming from Amazon's operational excellence initiatives is its unparalleled fulfillment and delivery network. By investing heavily in automation, robotics, and data analytics, Amazon has revolutionized the online shopping experience, offering customers fast and reliable delivery options, including same-day and even one-hour delivery in select areas. This commitment to operational efficiency has cemented Amazon's position as a market leader and set new standards for global operational excellence.

McDonald's Corporation: McDonald's is recognized for its consistent operational excellence in the quick-service restaurant industry. One standout achievement resulting from McDonald's operational excellence is its standardized and efficient food preparation and service processes. Through meticulous attention to detail, training programs, and technology integration, McDonald's has optimized its operations to deliver fast, accurate, consistent food quality across thousands of locations worldwide. This has contributed to McDonald's ability to serve billions of customers annually while maintaining high levels of customer satisfaction and brand loyalty.

Walmart Inc.: Walmart is lauded for its operational excellence in retail, demonstrated by its efficient supply chain management and inventory control practices. One notable achievement stemming from Walmart's operational excellence initiatives is its renowned everyday low prices (EDLP) strategy. Through rigorous cost management, supplier partnerships, and advanced forecasting algorithms, Walmart consistently offers competitive prices on various products, attracting millions of customers to its stores and online platforms. This commitment to operational efficiency has solidified Walmart's position as the world's largest retailer and enabled it to sustain growth and profitability in a highly competitive market.

Operational excellence is paramount for business leaders as it directly impacts an organization's ability to achieve its strategic objectives, maintain competitiveness, and drive sustainable growth. By prioritizing operational excellence, leaders can optimize processes, enhance efficiency, and deliver superior products and services to customers, fostering loyalty and satisfaction. Operational excellence enables leaders to adapt quickly to market changes, mitigate risks, and capitalize on new opportunities, ensuring long-term success and resilience in dynamic business environments.

Business leaders should regularly evaluate and enhance their operational strategies to drive excellence by embracing a culture of continuous improvement and innovation. This involves actively engaging employees, fostering collaboration, and investing in technologies and methodologies that streamline operations and enhance productivity. By setting clear goals, measuring performance, and soliciting stakeholder feedback, leaders can identify areas for improvement and implement targeted initiatives to drive operational excellence. Ultimately, by championing operational excellence, leaders can position their organizations for sustained success and maintain a competitive advantage in a rapidly evolving marketplace.

KaiNexus, on the other hand, was developed precisely for managing BOTH continuous improvement and innovation in the same platform, no matter which methodologies your organization uses. This flexibility is evident in the wide range of features that support all elements of top-down innovation and bottom-up improvement:

Copyright © 2026

Privacy Policy